Downflow Booth Systems

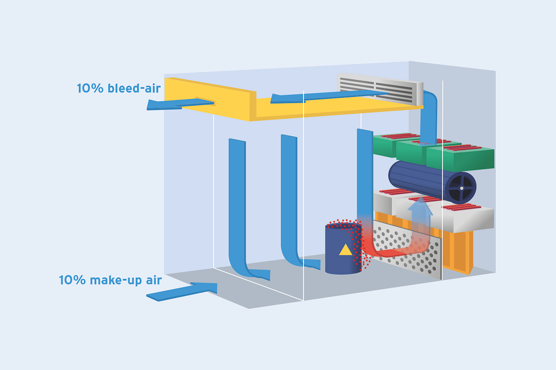

Two different principles

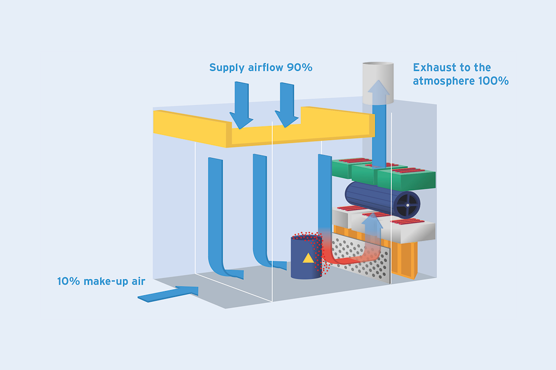

Our downflow booth systems are available in two different formats: Recirculation Downflow and Single Pass. See the illustrations below for an explanation of each format.

Recirculation Downflow

A Laminar Downflow Booth is a self-contained system designed to control potent or non-potent compounds/powders during sampling, weighing, and other manual processes.

Single

Pass

Booths with single-pass airflow systems are used when manual processes are required during sampling and weighing processes of liquids, solvents and powders, The once-through airflow format ensures and airborne substance is taken away from the operators breathing zone.

Recirculation Downflow

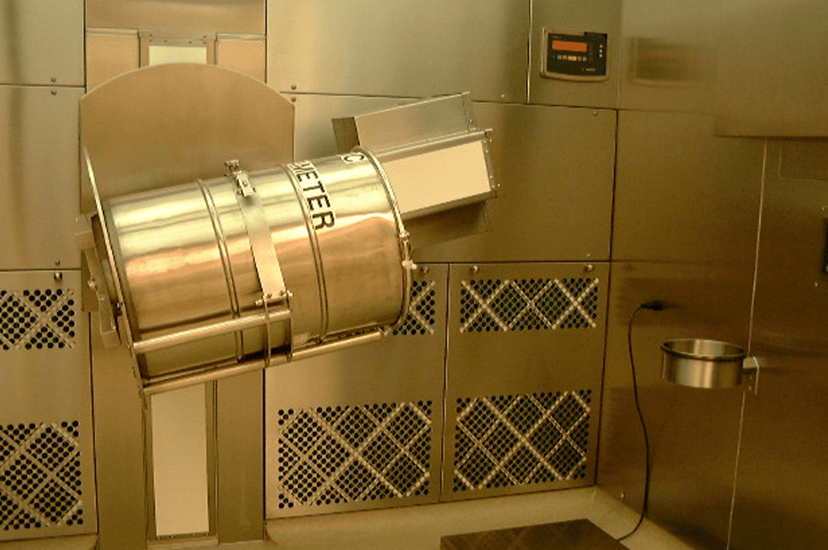

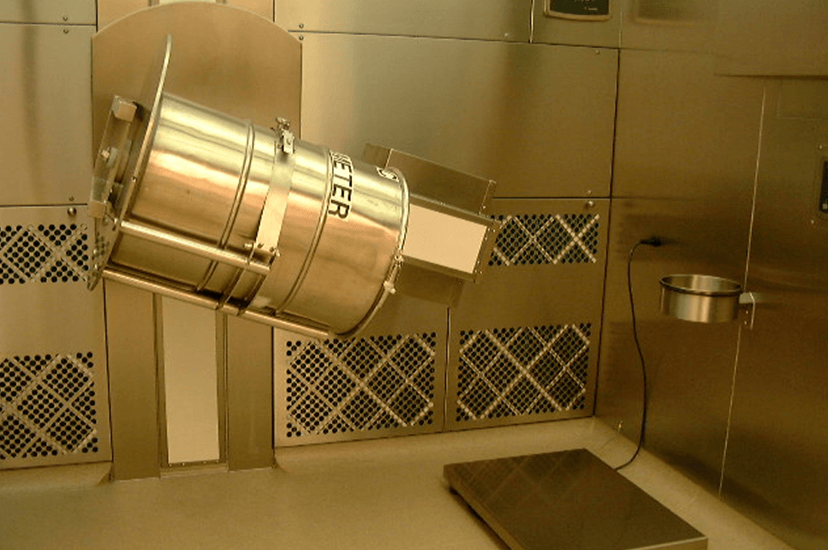

Powder Handling

Powder Handling booths allow materials to be transferred between a vast array of receptacles providing both operator and product protection.

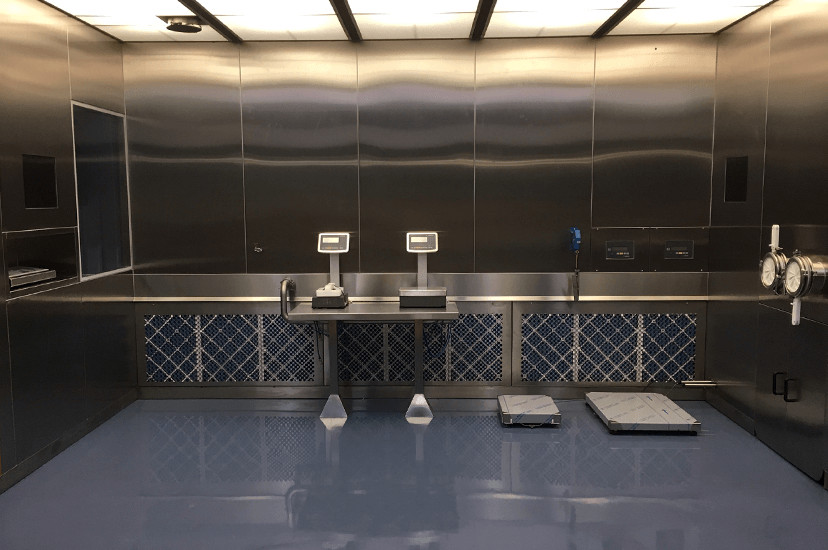

Sampling

Sampling booths are often found in uncontrolled environment areas, the sampling booth creates a safe contained location for sampling of raw materials.

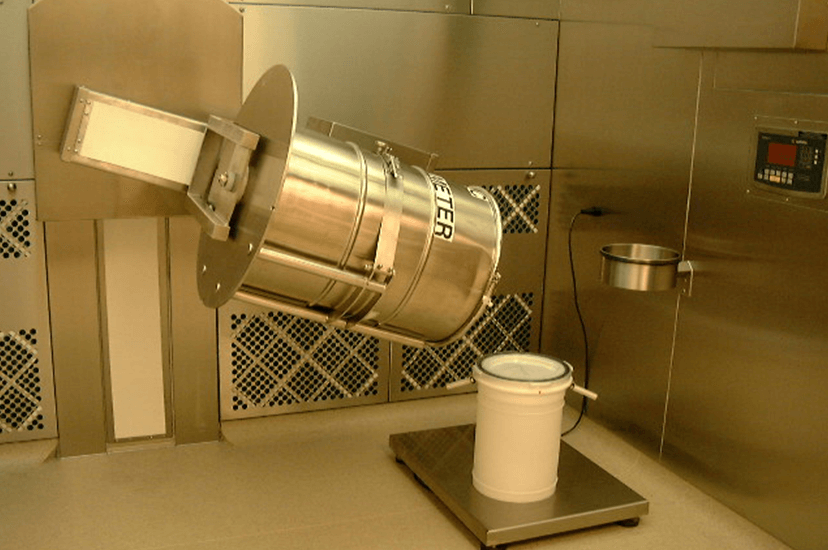

Dispensary

Dispensary and weighing booths are designed to accommodate the required weighing equipment, operational tools and the product all within a safe working area giving high levels of both operator and product protection.

Single Pass

Powder Handling

Powder Handling booths allow materials to be transferred between a vast array of receptacles providing both operator and product protection.

Sampling

Sampling booths are often found in uncontrolled environment areas, the sampling booth creates a safe contained location for sampling of raw materials.

Dispensary

Dispensary and weighing booths are designed to accommodate the required weighing equipment, operational tools and the product all within a safe working area giving high levels of both operator and product protection.

Solvent and Liquid Handling

Designed to be installed outside the client’s facility, the booth will provide a safe environment for the cleaning of components with solvents. Electrical components upgraded ATEX zone 1.